"Mastering the Three Body Problem: Optimizing Inventory, Warehouse Space, and Cash Flow for Business Success"

“We’ve expanded our warehouse, but it feels like we’re constantly running out of space. I can never find what I need, and I’m starting to wonder if we even have the stock, we think we do. We’re losing time and money just trying to keep things organized.”

“Every Onam or Diwali season, we stock up on apparel anticipating high demand, but somehow we either run out of popular items too soon or are left with piles of unsold stock. Our warehouse is a mess during this time; staff struggle to find the right products quickly, and we end up disappointing customers with delayed deliveries or stockouts. It’s chaotic, and we’re losing sales and reputation because of it.”

Sounds familiar? “You’re not alone”.

Many businesses face the same issue where Quantity, Space, and Time seem to be in constant conflict. It’s what we call the ‘Three Body Problem’ in business.

The good news? With the right strategies, you can turn these challenges into opportunities for growth and efficiency.”

In the realm of business, particularly within trading industries, there exists a “Three Body Problem” that challenges companies in their pursuit of efficiency and profitability. Unlike its origins in physics, where the problem involves the gravitational interactions between three celestial bodies, the business equivalent revolves around three critical factors: Quantity, Space, and Time. These three elements are deeply interconnected, and managing their interplay effectively is essential for sustained success.

Understanding the Three Bodies

- Quantity: Managing Inventory Levels

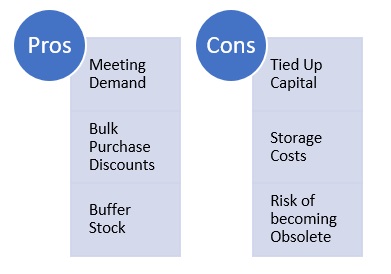

Quantity refers to the amount of goods a business decides to purchase, produce, or keep in stock at any given time. Managing quantity involves balancing supply with demand to ensure that there is neither too much nor too little inventory on hand.

Key Considerations:

Demand Forecasting: Accurate demand forecasting is crucial to balance inventory levels. Tools like predictive analytics can help businesses anticipate demand and adjust inventory accordingly.

Inventory Turnover Ratio: Monitoring the inventory turnover ratio helps ensure that stock is moving efficiently, minimizing excess or obsolete inventory.

- Space: Maximizing Physical Storage Capacity

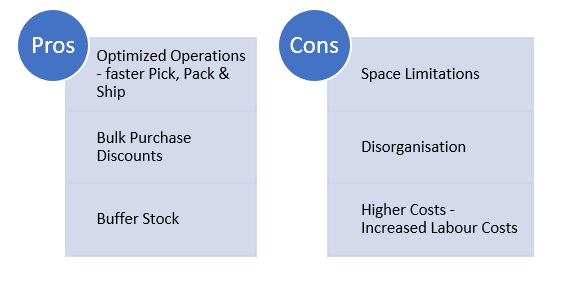

Space refers to the physical area available for storing inventory. Efficient use of space is critical for maintaining organized operations and reducing storage costs.

Key Considerations:

Warehouse Layout: Designing an efficient warehouse layout with optimized shelving, stacking, and pathways can maximize usable space.

Vertical Storage: Utilizing vertical space through stacking or mezzanine floors can significantly increase storage capacity without expanding the warehouse footprint.

Inventory Categorization: Implementing a systematic approach to categorizing and storing inventory can streamline operations and reduce retrieval times.

- Time: Synchronizing Supply Chain and Operations

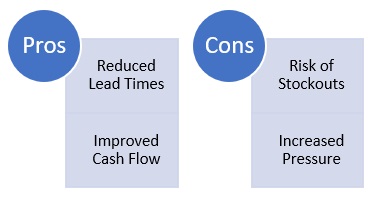

Time refers to the timing and duration of various business processes, including ordering, production, storage, and delivery. Efficient time management ensures that products move through the supply chain smoothly and reach customers when needed.

Key Considerations:

Lead Time Analysis: Regularly analyzing and optimizing lead times for ordering, production, and delivery can help ensure that products are available when needed.

Seasonal Planning: For businesses with seasonal demand, careful planning and timing of inventory purchases and promotions are essential to capture peak sales opportunities.

Supplier Relationships: Building strong relationships with reliable suppliers can help ensure timely deliveries and reduce the risk of delays.

Scenario: Plywood Trading Company

A plywood trading company deals in a variety of plywood types used in construction and furniture-making. The company needs to carefully manage the quantity of plywood it stocks, efficiently utilize the space in its warehouses, and time its orders to align with fluctuating demand in the construction industry. Additionally, implementing effective marking systems and using pallets are crucial for optimizing operations.

Quantity:

Challenge: Demand for plywood can be unpredictable, influenced by factors such as construction projects, economic conditions, and seasonality. Overstocking could lead to tied-up capital and the risk of damage due to prolonged storage, while understocking might cause delays in fulfilling orders, leading to customer dissatisfaction.

Solution:

Demand Forecasting: Implement a demand forecasting system that uses historical data, market trends, and real-time analytics to predict the quantity of plywood needed. This ensures they maintain an optimal stock level without overextending their resources.

Use of Pallets: Storing plywood on pallets not only protects the material from moisture and damage but also makes it easier to move and count large quantities. Pallets can be used to stack plywood vertically, maximizing space and simplifying inventory management.

Space:

Challenge: Plywood sheets are large and require significant storage space. Efficient use of warehouse space is critical to avoid clutter and ensure easy access to different types and sizes.

Solution:

Warehouse Layout Optimization: Organize the warehouse layout to maximize vertical space and categorize plywood based on type, size, and grade. Pallets play a crucial role in this layout, as they allow for better stacking and easier movement using forklifts or pallet jacks.

Marking Systems: Implement a clear and consistent marking system on the pallets or the plywood itself, indicating type, size, grade, and date of arrival. This system helps in quickly identifying and retrieving the right product, reducing errors and improving efficiency.

Vertical Storage: Utilize vertical space effectively by stacking pallets of plywood. This method not only saves floor space but also helps in maintaining a more organized and accessible inventory.

Time:

Challenge: The timing of orders is crucial, especially when large construction projects create sudden spikes in demand. Delays in receiving stock could disrupt the supply chain, affecting customer relationships.

Solution:

Supplier Coordination: Develop strong relationships with suppliers to ensure timely deliveries. Consider implementing just-in-time (JIT) inventory practices where possible, which rely on accurate timing to minimize inventory holding costs and reduce the risk of overstocking.

Marking and Tracking: Use the marking system to track the time-sensitive aspects of inventory, such as arrival dates and shelf life. This ensures that older stock is used first (FIFO), reducing waste and ensuring that customers receive fresh, high-quality plywood.

Palletized Delivery: Ensure that deliveries are palletized and marked correctly, which not only speeds up unloading and storage but also aligns with JIT practices by enabling quick restocking and minimizing disruption to warehouse operations.

Additional Considerations:

Safety and Accessibility: The use of pallets and a well-organized marking system contributes to safer warehouse operations. Properly stacked and marked pallets reduce the risk of accidents and make it easier for workers to access the required plywood efficiently.

Scenario: Apparel Trading Business (Seasons – Diwali / Onam)

An apparel trading business specializes in selling clothing during the Diwali/Onam season, a peak shopping period. They need to plan their inventory, space, and timing to capitalize on the seasonal demand surge.

Quantity:

Challenge: The season brings a significant increase in demand for traditional and festive wear. However, overestimating this demand could leave the business with excess stock after the season, leading to markdowns and reduced profitability.

Solution: Use data from previous seasons to forecast demand more accurately. Consider ordering a diverse range of sizes and styles in limited quantities to test the market before committing to larger orders.

Space:

Challenge: The seasonal nature of the business means that space needs fluctuate. The storage of off-season inventory can be a challenge, especially when preparing for the Diwali rush.

Solution: Implement a flexible storage system that can expand during peak season and contract during off-peak times. Outsource storage during peak periods if necessary or use temporary shelving solutions to accommodate increased inventory.

Time:

Challenge: Timing is everything during the peak season. Stock needs to be available in-store well before the festival begins.

Solution: Begin procurement and production well in advance of the season, factoring in lead times and potential delays. Launch marketing campaigns early to gauge demand and adjust inventory levels accordingly.

Each of these examples highlights the importance of managing Quantity, Space, and Time effectively in trading industries. Whether dealing with bulky plywood sheets, seasonal apparel, or large home appliances, the interplay between these three factors can significantly impact a business’s profitability and customer satisfaction.

At Leap Point, we understand the unique challenges faced by trading businesses. Being Sector Agnostic Business Consultants, our expertise can help you optimize these critical elements, ensuring that your business remains competitive and successful in a dynamic market.